Maintaining your batteries in the correct manner throughout the sweltering summer months is just as essential as doing so during the bone-chilling winter months. Your company is kept running by the batteries in your vehicle. To ensure that your battery lasts as long as possible, refer to this checklist:

Preventative Maintenance

Checking and confirming the following items should be done during the planned preventive maintenance (PM):

- The connections to the battery are spotless and free of any contaminants.

- The connections for the battery are secure.

- Hold-downs are fastened in an appropriate manner

- The battery pack has been charged to capacity.

- Examination of the Battery

Check the truck’s battery pack as part of your routine preventative maintenance on the vehicle, as well as any time the driver reports encountering “hard starts” when the truck is being utilized for shorter trips semi-truckrying heavy loads. During the testing of the battery pack, be sure to keep an eye out for the following factors:

The amount of charge retained in the battery pack

When fully charged, flooded batteries reach a voltage of 12.6 volts, whereas AGM batteries reach a voltage of 12.8 volts. Both the hold-downs and the battery connectors are tightened to a secure level. After being completely recharged, batteries are put through a series of tests using either a load or conductance tester. Examine the loads that are being utilized as well as the amount of extra power that is being used due to the increased operation of the air conditioner during the warmer months. If the battery pack is more than two to three years old, the user should think about changing the batteries in order to limit the likelihood of a no-start scenario or the need for urgent repairs.

Evaluation of Conductance

Conductance examines how a battery reacts to a very low-level signal in order to make an educated guess as to how it would react to a much higher-level current. When doing conductance tests on depleted batteries, you won’t get accurate results. If it is known that the battery is low on power, or if the tester instructs the operator to charge the battery before continuing with the test, the battery has to be entirely recharged.

State-of-Charge

The open circuit voltage (OCV) is used to make an estimate of the battery’s state-of-charge, which is then used to assess whether or not the battery is in a testing condition or to calculate how long it will take to charge the battery. Important to note:

Battery design varies

- The charge schedules include a display of the typical values.

- For the majority of tests, a charge state of at least 75%, preferably 75%, is required.

- Any recent action will produce an increase in the OCV over the amount that would be considered to be in equilibrium.

As was indicated previously, there are significant differences between the various types of batteries. They are not usually interchangeable since each of them is responsible for a unique function. Therefore, instead of obtaining affordable replacement batteries in bulk, you should start getting the appropriate battery for the equipment you have. When shopping for batteries, the rating and the kind are the two most important characteristics to look at. The rating will help you understand the cold-cranking amps, also known as the amount of current that can be provided when the temperature is low, as well as the RC (the reserve capacity – how much power can be stored once charged). Always be sure to verify the directions before beginning the charging process. It is never a bad idea to review previous steps, even if you have completed them a thousand times. Many commercial batteries have threaded stud terminals, which means that in order to charge them, you need specific charging posts. A flush connection to the terminal may be achieved using the posts. If you connect straight to the threaded stud, you won’t receive the lead-to-lead contact that’s necessary to produce a good charge and accurate readings.

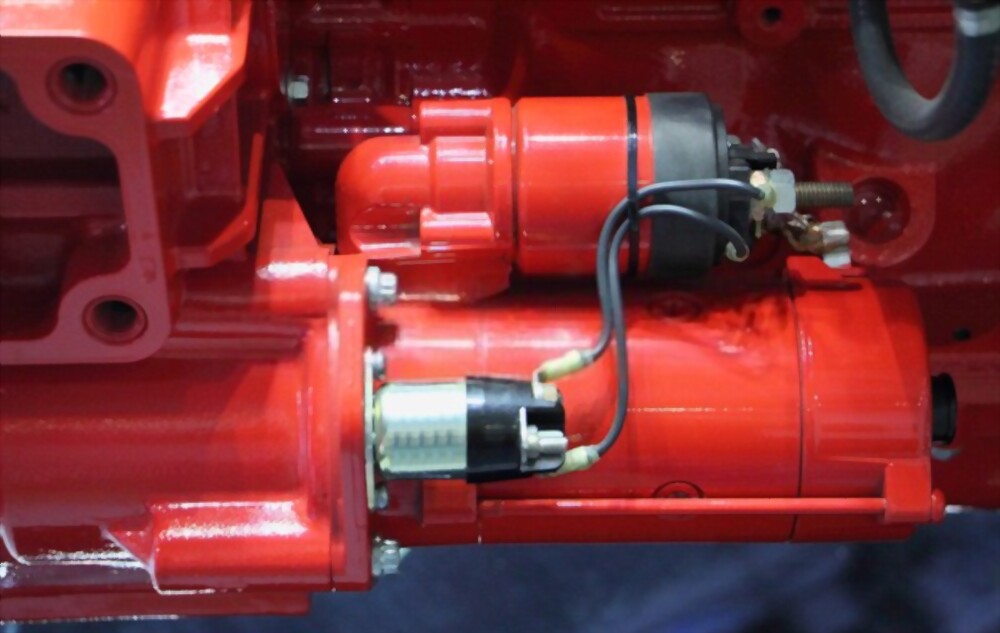

Alternators and starters are typically not considered by drivers until their semi-truck refuses to start for no apparent reason. Simple enough: The starter depends on the battery, the alternator depends on the starter (skipping a few steps), and the battery depends on the alternator.

Our professionals at A&S know how to get your automobile operating again. If your battery is in good condition, we examine the alternator, starter, and other potential parts of your starting system, such as the ignition switch and drive belts. Before starting any repairs, we then go over the condition of your semi-truck and offer a written estimate.

Your semi-truck’s starter really kicks off your engine’s combustion process. The starter receives electricity from the battery when you crank or press your ignition. The starting motor starts the engine by turning a gear attached to the crankshaft. Many mistakenly believe that the loud clicking sound they hear when their battery dies is the starting relay failing due to inadequate power from the battery. The voltage of your battery is checked first when evaluating your starter, much like the alternator. A semi-truck starter does not have a set replacement cycle in the industry, and your original component could never need to be changed. But here are some indications that you should replace your starter:

- Especially if you hear a loud click instead of the engine starting (and your battery is healthy).

- The engine doesn’t always crank (and your battery is healthy).

- Throughout the whole trip, the starter grinds (the starter fails to turn off).